The machine appearance

Touch screen start adjustment is convenient and quick, sawing length can be adjusted arbitrarily

The downward pressure of all cylinders can be adjusted to ensure product quality

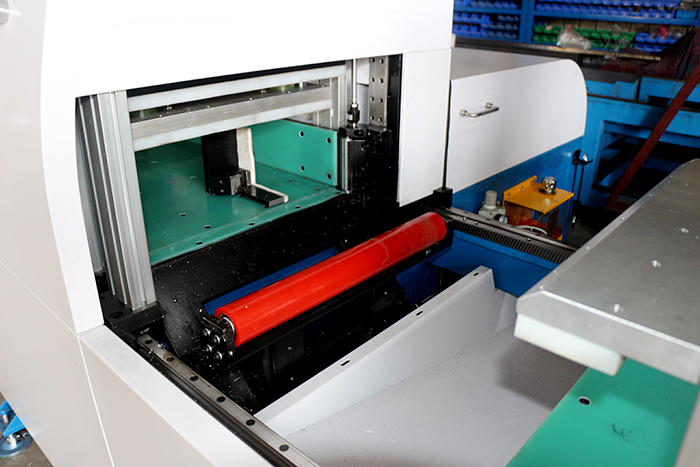

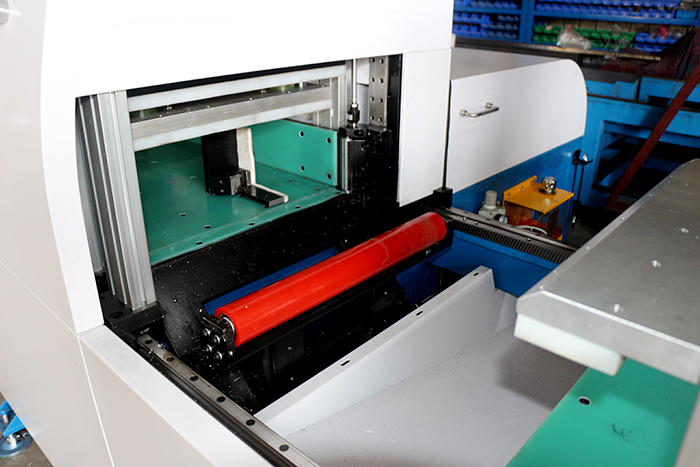

The feeding roller can be lifted up and down to avoid scratching the material surface. The shortest material can be cut to 30mm

Feed using servo motor, stable operation

After sawing, the two sides can be separated. The sawing precision is high, and the end face is smooth. The belt is made of multi-wedge belt, and the vibration of the whole machine is small.

No need to set the material length, no material automatic recognition induction

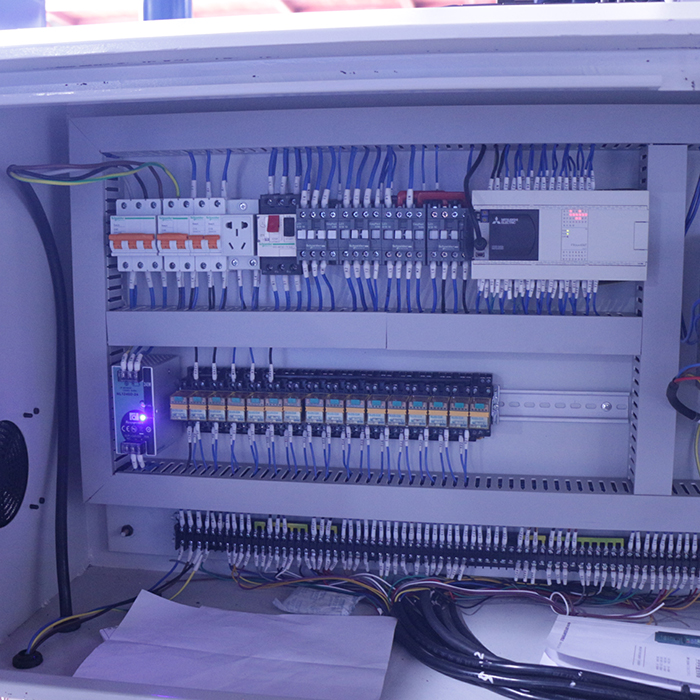

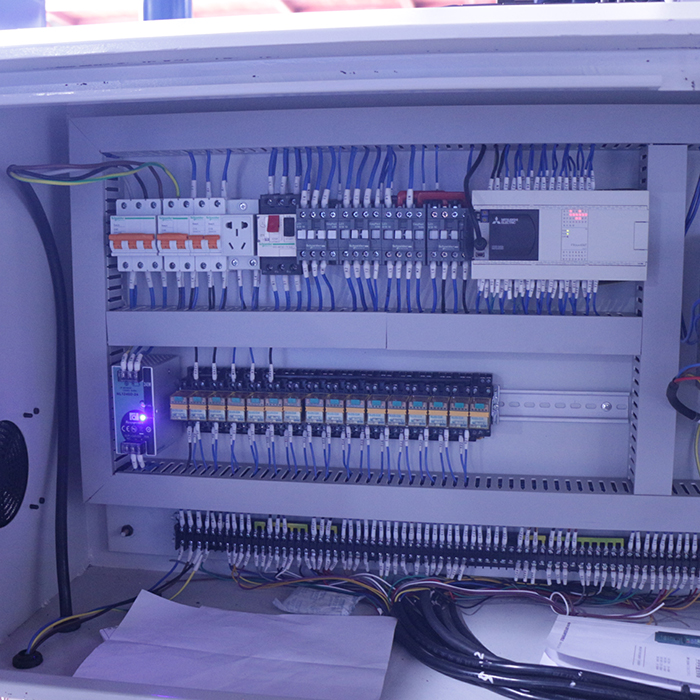

Electric box is clean and simple

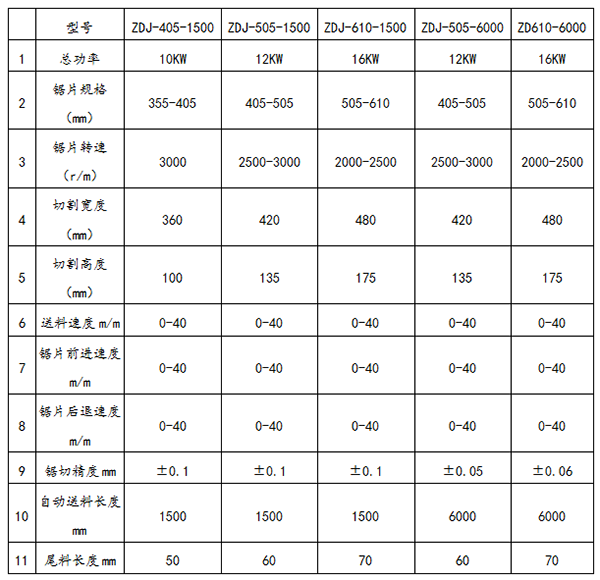

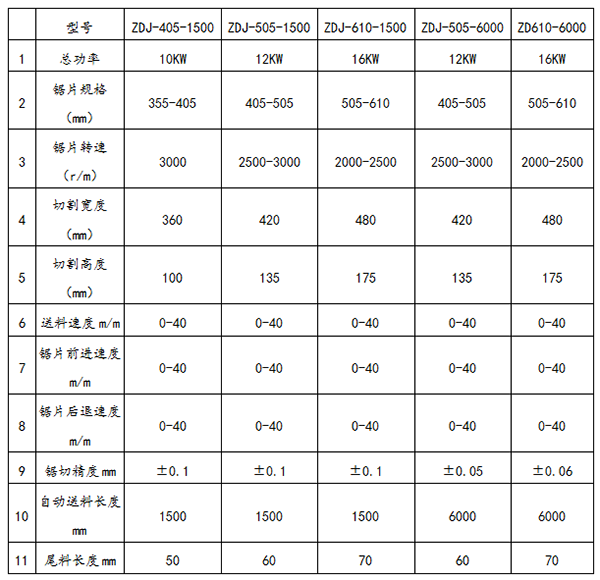

Our independent research and development of the tailless automatic saw table, can realize automatic feeding, automatic sawing;

1. Special sawing action design (cutting back and discharging) : after the saw blade cuts off the material in straight line, the sawing profile is pulled open by PLC control, and the saw blade returns to the origin to ensure the sawing precision;

2, Adopt servo motor with high precision grinding rack, add electronic ruler, accurate positioning; The use of PLC control, trace lubrication oil injection system, lubrication and cooling saw blade, prolong the life of the saw blade;

3. Realize intelligent automation, save people, effort and time to reduce costs, improve quality, simple and convenient operation and increase efficiency.